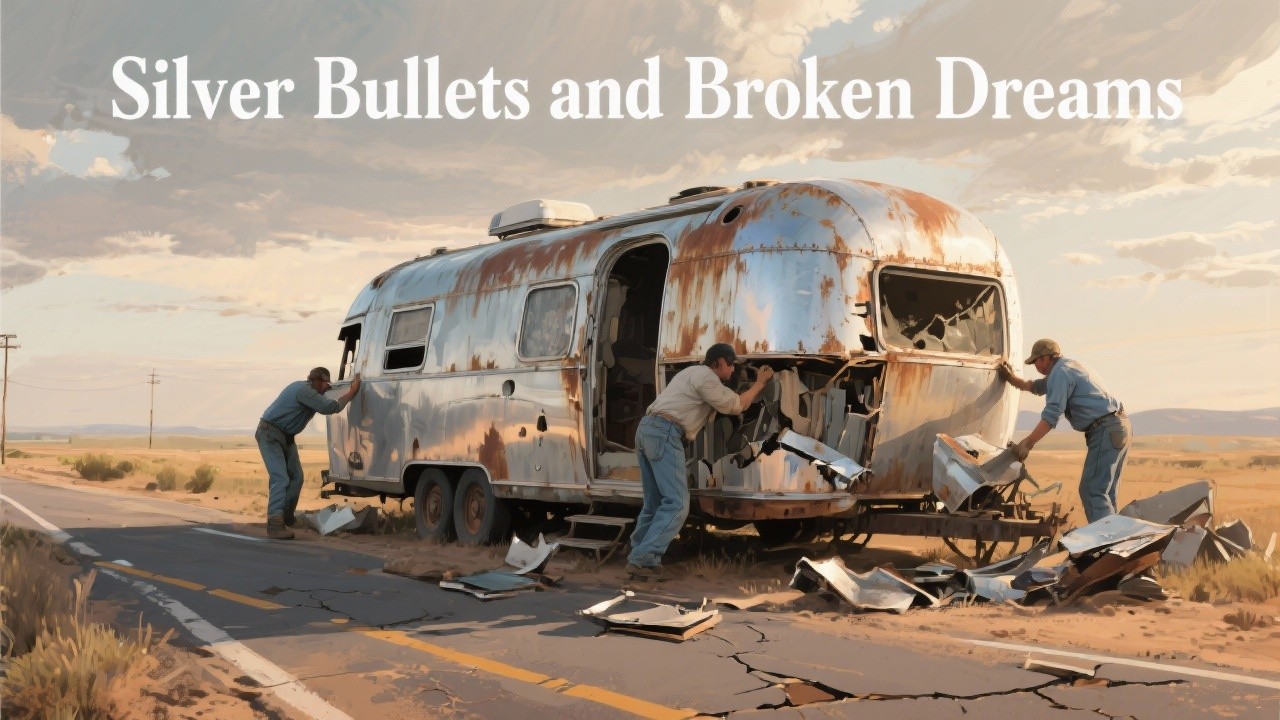

Vintage Airstream restoration represents the Mount Everest of RV renovation projects—technically demanding, financially daunting, yet irresistibly alluring to those seduced by aluminum curves and mid-century charm. These iconic travel trailers, built between 1931 and the 1990s, promise a unique blend of American craftsmanship and timeless design that no modern RV can replicate.

Aluminum Archaeology: Decoding Decades of Airstream DNA

Each Airstream era carries distinct characteristics that dramatically impact restoration complexity and cost. Understanding these generational differences separates successful restorations from expensive disasters. Airstream’s heritage archives reveal that construction techniques evolved radically across decades, creating vastly different restoration challenges.

The Golden Age Breakdown

Pre-1969 Airstreams feature coveted 13-panel end caps and steel frames that survive decades but hide serious rust. The 1970s introduced aluminum frames—lighter but prone to stress cracks. The 1980s brought improved insulation but problematic grey tanks. Each era demands specific expertise, with pre-1960 models commanding premium prices despite requiring complete frame-off restorations.

| Era | Key Features | Common Issues | Restoration Hours | Market Value Range |

|---|---|---|---|---|

| 1950s | Steel frame, 13-panel | Frame rust, whale tail damage | 1,500-2,000 | $35,000-$85,000 |

| 1960s | Steel frame, classic interior | Floor rot, window leaks | 1,200-1,800 | $25,000-$65,000 |

| 1970s | Aluminum frame begins | Frame cracks, subfloor issues | 1,000-1,500 | $18,000-$45,000 |

| 1980s | Improved systems | Clear coat failure, tank problems | 800-1,200 | $15,000-$35,000 |

| 1990s | Modern amenities | Interior plastics degradation | 600-1,000 | $20,000-$40,000 |

The Pre-Purchase Autopsy: Forensic Evaluation Techniques

Buying a vintage Airstream without thorough inspection guarantees financial hemorrhaging. Professional evaluators charge $500-$1,000 for comprehensive assessments, but their expertise prevents $20,000+ surprises. Smart buyers perform preliminary evaluations themselves, knowing exactly where aluminum beauties hide their darkest secrets.

Experienced restorers developed a 20-point inspection focusing on frame integrity, shell separation, floor rot, axle condition, and electrical systems. Failing any three points typically doubles restoration costs. The most critical inspection point—the rear frame section where 73% of catastrophic failures originate—requires crawling underneath with moisture meters and inspection cameras.

Shell Shock: Reading Aluminum Tea Leaves

Airstream shells communicate through subtle signals invisible to untrained eyes. Microscopic stress cracks near windows forecast $5,000 repairs. Slight buckling at belt lines indicates frame problems requiring $15,000 solutions. The Vintage Airstream Club maintains detailed guides mapping common failure points by model year.

The Tennessee Tragedy

Mark and Jennifer Williams bought a “restored” 1967 Airstream for $32,000 based on photos. Delivery revealed professional paint hiding extensive shell damage. The aluminum skin separated from frame members, requiring complete disassembly. Their $32,000 bargain became a $78,000 project. The seller had strategically photographed angles concealing separation gaps visible only in person.

The Moisture Mapping Mission

Water damage remains the silent killer of vintage Airstreams. Professional moisture meters reveal hidden rot that visual inspection misses. Testing protocols involve checking 50+ points, with readings above 15% indicating problems. Smart buyers create moisture maps, documenting readings that become negotiation ammunition or walk-away warnings.

Vintage dealers hate educated buyers who arrive with infrared cameras. These $300 devices reveal water intrusion, delamination, and insulation gaps invisible to naked eyes. Temperature variations of 5°F indicate moisture problems. One infrared inspection prevented a buyer from purchasing an Airstream with $25,000 in hidden water damage professionally concealed with fresh interior paint.

Financial Forensics: The True Cost of Aluminum Dreams

Restoration budgets explode faster than champagne bottles at Airstream rallies. Initial estimates routinely triple as hidden damage emerges. Understanding cost escalation patterns prevents bankruptcy and divorce—both common casualties of underestimated Airstream projects.

| Restoration Level | Scope | DIY Cost | Professional Cost | Timeline |

|---|---|---|---|---|

| Cosmetic Refresh | Paint, interior updates | $5,000-$10,000 | $15,000-$25,000 | 3-6 months |

| Systems Overhaul | Electrical, plumbing, appliances | $10,000-$20,000 | $25,000-$40,000 | 6-9 months |

| Shell-On Restoration | Complete interior, partial structure | $20,000-$35,000 | $45,000-$70,000 | 12-18 months |

| Frame-Off Restoration | Complete disassembly/rebuild | $35,000-$60,000 | $75,000-$150,000 | 18-36 months |

| Concours Quality | Show-winning perfection | $60,000+ | $150,000+ | 2-4 years |

Hidden Cost Multipliers Nobody Mentions

Specialty Tools Rental/Purchase: $2,000-$5,000

Disposal Fees (asbestos, tanks): $1,500-$3,000

Storage During Restoration: $200-$400/month

Transportation to Specialists: $1,000-$3,000

Marriage Counseling: $2,000-$5,000

Actual Cost = Estimated × 2.5 (minimum)

Structural Surgery: Frame and Shell Resurrection

Frame restoration separates hobbyists from professionals. Steel frames in pre-1970 models rust from inside out, appearing solid while harboring catastrophic weakness. Aluminum frames crack at stress points, requiring specialized welding that few shops perform correctly.

Never attempt frame repairs without engineering consultation. Improper welding creates stress concentrations causing highway-speed failures. Three Airstream owners died in 2019-2020 from frame failures following DIY repairs. Professional frame restoration costs $8,000-$15,000 but prevents tragedy. Insurance companies increasingly require certified frame inspections for vintage Airstream coverage.

The Belly Pan Battleground

Belly pans—the aluminum sheets protecting undersides—conceal horrors. Removing them reveals mouse colonies, rust graveyards, and rotted floors. Airstream Forums document hundreds of restoration projects derailed by belly pan surprises. Budget $3,000-$5,000 for belly pan restoration alone.

The Michigan Mouse Mansion

A pristine-looking 1972 Airstream sold for $18,000. Belly pan removal revealed 40 years of mouse damage—chewed wiring, destroyed insulation, and 200 pounds of nesting material. The biohazard cleanup alone cost $2,500. Complete floor replacement, rewiring, and insulation added $22,000. The “bargain” Airstream ultimately cost $42,500, still below professional restoration prices but triple the initial investment.

Rivet Reality: The 3,000-Piece Aluminum Puzzle

Each Airstream contains 3,000-4,000 rivets, and restoration often requires replacing 20-30%. Olympic riveting—the specialized technique for aircraft-grade installation—demands specific tools and skills. Amateur riveting creates leaks, stress points, and that dreaded “backyard restoration” appearance that destroys value.

Buck rivets—solid aluminum fasteners requiring two-person installation—provide superior strength over pop rivets. Professional restorers exclusively use buck rivets for structural repairs, while pop rivets suffice for cosmetic applications. The difference: buck-riveted repairs last 50+ years, while pop rivets fail within 5-10 years under road stress.

Polishing Purgatory: 100 Hours to Mirror Finish

Achieving Instagram-worthy mirror finishes requires 100+ hours of progressive polishing. The process involves paint stripping, oxidation removal, four grades of polishing compound, and final waxing. Professional polishing costs $3,000-$5,000, while DIY attempts often create swirl marks requiring professional correction.

| Polishing Stage | Product | Time per Side | Result | Cost |

|---|---|---|---|---|

| Paint Stripping | Aircraft Stripper | 8-10 hours | Bare aluminum | $150 |

| Oxidation Removal | Alumabrite | 6-8 hours | Clean surface | $100 |

| Coarse Polish | Nuvite F7 | 10-12 hours | Satin finish | $75 |

| Fine Polish | Nuvite C | 8-10 hours | High shine | $75 |

| Final Polish | Nuvite S | 6-8 hours | Mirror finish | $75 |

Interior Archaeology: Preserving Mid-Century Magic

Original Airstream interiors represent irreplaceable time capsules of American design. Birch plywood, Zolatone paint, and period-correct fixtures command premium prices. Restoration philosophy divides between preservation (maintaining originality) and modernization (adding contemporary comfort).

The Subfloor Surprise

Airstream subfloors combine plywood with aluminum C-channels in complex sandwich constructions. Water damage necessitates complete replacement—a process requiring trailer lifting, shell support, and precise reconstruction. Vintage Airstream Parts supplies reproduction components, but installation remains challenging.

Subfloor Replacement Reality

Budget 200 hours for complete subfloor replacement. The process involves removing interior components, documenting C-channel positions, cutting custom plywood, treating with marine sealers, and reinstalling with aircraft adhesive. Material costs reach $2,000-$3,000, while professional installation adds $8,000-$12,000. Shortcuts using standard plywood create long-term failures.

Systems Integration: Modernizing Without Massacring

Updating 12-volt electrical, propane, and plumbing systems while maintaining vintage aesthetics challenges even experienced restorers. Modern safety requirements conflict with original designs, forcing creative solutions that satisfy inspectors without destroying authenticity.

Hide modern electrical panels behind vintage cabinet doors. Install inverters under gaucho seating. Route solar wiring through original wire chases. These invisible upgrades provide modern convenience while preserving showroom appearance. One restorer concealed a complete lithium battery bank inside a rebuilt icebox, maintaining 1950s aesthetics with 2020s power.

The Propane Predicament

Vintage Airstreams used interior propane appliances now illegal in many states. Conversion options include electric alternatives (sacrificing boondocking capability) or relocating tanks outside (altering aesthetics). Each choice impacts value and usability differently.

| System Upgrade | Original Preservation | Safety Compliance | Cost | Value Impact |

|---|---|---|---|---|

| Electrical Rewire | Hidden modern wiring | Full NEC compliance | $3,000-$5,000 | +$5,000 |

| Propane System | External tanks only | NFPA standards | $2,000-$3,500 | Neutral |

| Plumbing Update | PEX with vintage fixtures | Modern standards | $2,500-$4,000 | +$3,000 |

| Solar Addition | Portable panels | Not applicable | $1,500-$3,000 | +$2,000 |

| Lithium Batteries | Hidden installation | Proper venting | $2,000-$5,000 | +$4,000 |

Sourcing Secrets: The Underground Parts Network

Finding authentic Airstream parts resembles archaeological treasure hunting. Original components hide in barn sales, swap meets, and deceased estates. The underground network of parts dealers, hoarders, and traders operates through word-of-mouth, forums, and annual rallies.

The Great Vent Find of 2023

Restorer Jim Patterson needed rare 1958 ceiling vents—unavailable reproductions costing $800 each if custom-made. Through Airstream forums, he connected with an Idaho farmer demolishing a damaged vintage unit. For $200 plus shipping, he acquired six perfect vents, interior lights, and original badges. Network connections saved $4,600 while maintaining authenticity.

Reproduction Versus Original Dilemma

Quality reproductions from companies like Vintage Camper Trailers offer convenience but lack authenticity. Original parts command premium prices but provide correct patina and materials. Mixing reproduction and original components requires careful consideration of visibility and function.

Successful restorations maintain 70% original or period-correct components in visible areas while using 30% modern reproductions for hidden systems. This balance preserves value while ensuring reliability. Exceeding 50% reproduction parts transforms “restoration” into “renovation,” reducing value by 25-40%.

Professional Versus DIY: The Brutal Truth

Professional restoration shops charge $100-$150 hourly, transforming basket cases into concours winners. DIY restoration saves money but demands 1,500+ hours of skilled labor. Most enthusiasts underestimate the physical, emotional, and relationship toll of multi-year projects.

Airstream restoration forums document numerous divorces attributed to project stress. Partners envision romantic weekend projects but encounter two-year ordeals involving toxic chemicals, financial strain, and cancelled vacations. Successful couples establish clear boundaries: dedicated budgets, firm timelines, and agreement that relationships matter more than aluminum. Consider restoration’s impact beyond dollars and hours.

The Skills You Never Knew You Needed

Successful DIY restoration requires mastering aluminum welding, upholstery, electrical work, plumbing, carpentry, and polishing. Each skill demands specialized tools and significant practice. Most restorers discover hidden talents—or expensive limitations—through trial and error.

The YouTube University Graduate

Sarah Thompson spent 400 hours watching restoration videos before touching her 1964 Safari. Her methodical approach—practicing each skill on scrap materials—resulted in professional-quality results. Her investment: $2,000 in online courses, $5,000 in tools, and 1,800 hours over three years. The result sold for $65,000, validating her educational approach.

Market Mastery: Buying, Selling, and Value Trends

Vintage Airstream values fluctuate wildly based on condition, authenticity, and market timing. Understanding valuation factors prevents overpaying for projects or underpricing completed restorations. Hagerty’s collector vehicle insights track Airstream appreciation trends.

| Model Category | Purchase Price Range | Restoration Cost | Finished Value | ROI Potential |

|---|---|---|---|---|

| Rare/Vintage (pre-1960) | $5,000-$25,000 | $40,000-$80,000 | $60,000-$120,000 | 20-40% |

| Classic (1960s) | $3,000-$15,000 | $30,000-$60,000 | $35,000-$75,000 | 0-20% |

| Common (1970s) | $2,000-$10,000 | $25,000-$45,000 | $25,000-$50,000 | -10-10% |

| Modern Vintage (1980s) | $3,000-$12,000 | $20,000-$35,000 | $20,000-$40,000 | -20-0% |

| Bambi/Small Units | $8,000-$20,000 | $15,000-$30,000 | $30,000-$55,000 | 10-30% |

Rally Culture: The Secret Society of Silver Bullets

Vintage Airstream ownership includes membership in an exclusive culture. Rallies provide parts sources, technical expertise, and validation for restoration investments. Understanding this community proves essential for successful buying, selling, and enjoying restored Airstreams.

The Concours Competition Circuit

Airstream concours events judge restorations against exacting standards. Winning adds $10,000-$20,000 to resale values while establishing restoration credibility. Preparation requires obsessive attention to period-correct details that casual observers never notice but judges always catch.

Successful concours entries document everything—original sales receipts, restoration photographs, and component provenance. Judges deduct points for incorrect screws, modern materials, and non-original modifications regardless of quality. One restorer lost first place for using Phillips-head screws in pre-1960 applications requiring slotted fasteners—a detail costing championship recognition.

Questions That Haunt Every Prospective Restorer

The Aluminum Enlightenment: Your Restoration Reality Check

Vintage Airstream restoration transforms ordinary people into aluminum alchemists, teaching skills ranging from metallurgy to upholstery. Success requires accepting that perfection costs more than purchasing new Airstreams, timelines always double, and the journey matters more than destinations.

Most completed restorations cost more than their market value, yet owners rarely regret the investment. The education, community connections, and pride of resurrection provide intangible returns exceeding financial calculations. Every rivet driven, every hour polishing, and every problem solved contributes to a transformation extending beyond aluminum—you emerge different, carrying capabilities and confidence that no classroom could provide.

Those gleaming Airstreams at rallies represent more than restored travel trailers—they’re monuments to persistence, learning, and the distinctly American belief that anything worth saving deserves our best effort. Whether you join this community as buyer, restorer, or admirer, respect the dedication behind every mirror finish.

Your vintage Airstream journey begins with honest self-assessment. Calculate available time, money, and relationship capital before committing. If the numbers align and passion persists, join the thousands who’ve discovered that restoring an Airstream restores something within themselves. The aluminum may shine, but the real transformation happens to the person holding the polishing cloth.

Remember, every pristine vintage Airstream started as someone’s impossible dream, abandoned in a field or forgotten in a barn. Through knowledge, determination, and considerable investment, these aluminum phoenixes rise again. Your decision to restore or buy restored shapes not just your camping future but your participation in preserving American recreational history.

Leave a Reply